Mastering the Art of Paint Correction with finesse polishing compound

In the world of automotive detailing, achieving a showroom-quality finish requires more than just basic cleaners and waxes—it demands precision abrasives designed to correct paint defects while delivering a brilliant gloss. Among these specialized products, the finesse polishing compound stands out as a crucial tool for detailers, body shops, and car enthusiasts who demand the ultimate balance between effective defect removal and impeccable surface clarity. This article will explore the industry knowledge surrounding finesse polishing compounds, introduce SYBON’s flagship Perfect Machine Polish, and demonstrate why SYBON is the cost-effective, high-quality partner you need to grow your business.

Understanding Finesse Polishing Compounds

A finesse polishing compound is formulated with ultra-fine abrasive particles that gently refine paint surfaces, eliminating micro-swirls, holograms, and light surface scratches left behind by more aggressive compounds. Unlike heavy cut compounds, which remove deeper scratches but often leave a dull haze, finesse formulas are optimized to:

- Deliver a high-gloss finish: Their microscopic abrasives smooth paint at a nanoscopic level, ensuring maximum reflectivity.

- Minimize removal rate: Controlled cutting action prevents over-thinning of clear coat layers, preserving paint integrity.

- Enhance clarity and depth: By refining the outermost layer, these compounds reveal richer color saturation and depth.

- Reduce heat buildup: Specialized lubricants help dissipate friction heat, allowing longer working times without risking paint damage.

Typical use cases for finesse polishing compounds include final finishing stages after heavier correction, spot corrections around sensitive edges, and maintenance polishing for lightly weathered vehicles. When paired with the appropriate foam or microfiber pad and a dual-action or rotary polisher, finesse compounds unleash their full potential, leaving surfaces that appear mirror-like under direct lighting.

Key Benefits of Using Finesse Polishing Compounds

1. Safe Defect Refinement

Finesse compounds strike the perfect balance between cutting power and gentleness, ensuring that light scratches and swirl marks are removed without compromising the clear coat’s thickness.

2. Time Efficiency

The fine abrasives work quickly to level surface irregularities, reducing the need for multiple polishing passes and saving labor time—an essential factor for professional shops handling multiple vehicles daily.

3. Enhanced Customer Satisfaction

A brilliantly smooth finish not only looks impressive but also makes subsequent wax or sealant applications more effective, resulting in longer-lasting protection and delighted customers who appreciate the flawless showroom shine.

4. Versatility

From light paint correction to periodic maintenance, finesse polishing compounds adapt to various detailing scenarios, making them indispensable for comprehensive service offerings.

Choosing and Applying a Finesse Polishing Compound

To maximize the performance of a finesse polishing compound, consider the following:

- Pad Selection: Use soft foam or low-nap microfiber pads to complement the fine abrasive particles.

- Polisher Type: Dual-action polishers are ideal for novices and intricate areas, while rotary machines can leverage higher speeds for professionals seeking faster cutting.

- Speed and Pressure: Moderate RPM settings (1,500–2,500 RPM) combined with light to medium downward pressure ensure controlled removal without heat-induced burns.

- Work Area and Clean-Up: Section the paint surface into manageable zones, and wipe away residue with a plush microfiber towel to evaluate the finish before moving on.

SYBON’s Perfect Machine Polish: The Ultimate Finesse Polishing Compound

Building on decades of expertise in abrasive technology, SYBON proudly presents Perfect Machine Polish—a top-tier finesse polishing compound engineered for professionals and enthusiasts alike. Key features include:

- Advanced Abrasives

Precisely engineered particles deliver uniform cutting action and fade out cleanly, ensuring a swirl-free, dazzling finish every time.

- Balanced Formula

Our formula optimizes the ratio of abrasives to lubricants, extending working time and reducing dusting for faster, cleaner application.

- Clear Coat Safety

Perfect Machine Polish is pH-neutral and free of harsh solvents, safeguarding modern OEM and aftermarket clear coats.

- User-Friendly Consistency

Creamy texture adheres to pads without sling-off, enabling precise control even on vertical surfaces.

Whether you’re removing light oxidation or performing the final polish after aggressive correction, SYBON’s Perfect Machine Polish excels as a genuine finesse polishing compound, producing results on par with major international brands.

Quality That Rivals Big Brands—At a Superior Price

While SYBON may not yet have the global name recognition of some legacy brands, our commitment to rigorous quality control and modern production standards ensures our products deliver equivalent performance. By manufacturing directly in our state-of-the-art facilities in China and maintaining lean distribution channels, we offer:

- Competitive Pricing

Up to 30% savings compared to leading brand equivalents—allowing you to achieve premium results while preserving healthy margins.

- Consistent Batch-to-Batch Quality

Automated mixing and precision testing equipment guarantee uniform performance, so every bottle of Perfect Machine Polish performs identically.

- High Cost-Performance Ratio

Exceptional finishing power combined with cost savings empowers detailers and distributors to undercut local competition and expand market share.

Superior After-Sales Support

At SYBON, our relationship with customers doesn’t end at purchase. We provide:

- Technical Training

Online tutorials, in-person workshops, and one-on-one coaching sessions to optimize product usage.

- Marketing Materials

Custom-branded brochures, demo videos, and display stands to help you promote SYBON’s solutions effectively.

- Responsive Customer Service

Dedicated support teams available 24/7 to answer questions, troubleshoot application issues, and process orders with a 24-hour response guarantee.

Partner with SYBON—Global Opportunities Await

SYBON is actively seeking agents and distributors worldwide to bring our Perfect Machine Polish and full range of automotive care products to new markets. We cater to:

- Automotive Dealerships & Retailers

Expand your premium detailing services with our complete line of polishes, compounds, waxes, and sealants.

- Fleet Owners & Workshops

Enhance operational efficiency and output quality with high-performance abrasives that deliver consistent results.

- Paint & Body Shops

Achieve flawless paint corrections and finishing touches that satisfy the most discerning clients.

If you are an automotive care agent, paint shop owner, or repair center manager interested in becoming a SYBON distributor, we invite you to:

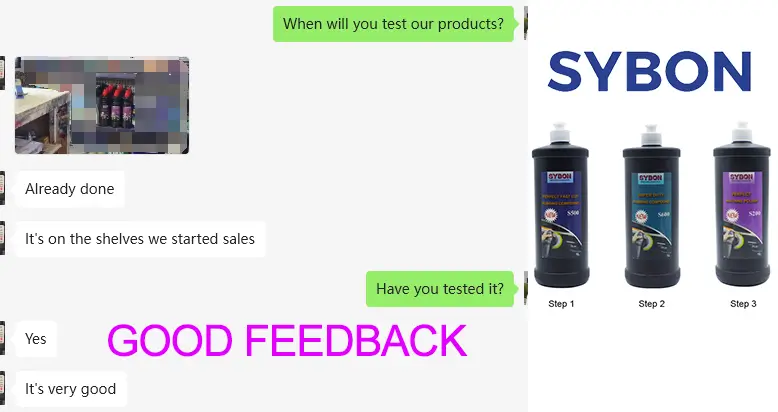

1. Request a Sample

Experience Perfect Machine Polish firsthand— samples are available for testing.

2. Discuss Partnership Details

Contact our global sales team via the inquiry form on our website or email us directly.

3. Grow Your Business

Leverage SYBON’s quality products, competitive pricing, and marketing support to boost your sales and customer satisfaction.

Reach out today through our website’s “Contact Us” page, and our team will respond within 24 hours. With SYBON as your partner, you gain not only a world-class finesse polishing compound but also a committed ally in expanding your market presence and enhancing your service offerings.

Conclusion

For professional-grade paint finishing that rivals leading brands—but at a fraction of the cost—look no further than SYBON’s Perfect Machine Polish. Our expertise in finesse polishing compounds, combined with rigorous manufacturing standards and exceptional after-sales service, makes us the premier choice for detailers, distributors, and dealers worldwide. Partner with SYBON today to elevate your automotive care business and deliver the flawless, high-gloss finishes that your customers demand.

Source of this article:https://www.sybonbest.com

Get to know us through more channels: