Coarse Polishing Compounds — The Essential Guide for Heavy Defect Removal and Efficient Paint Restoration

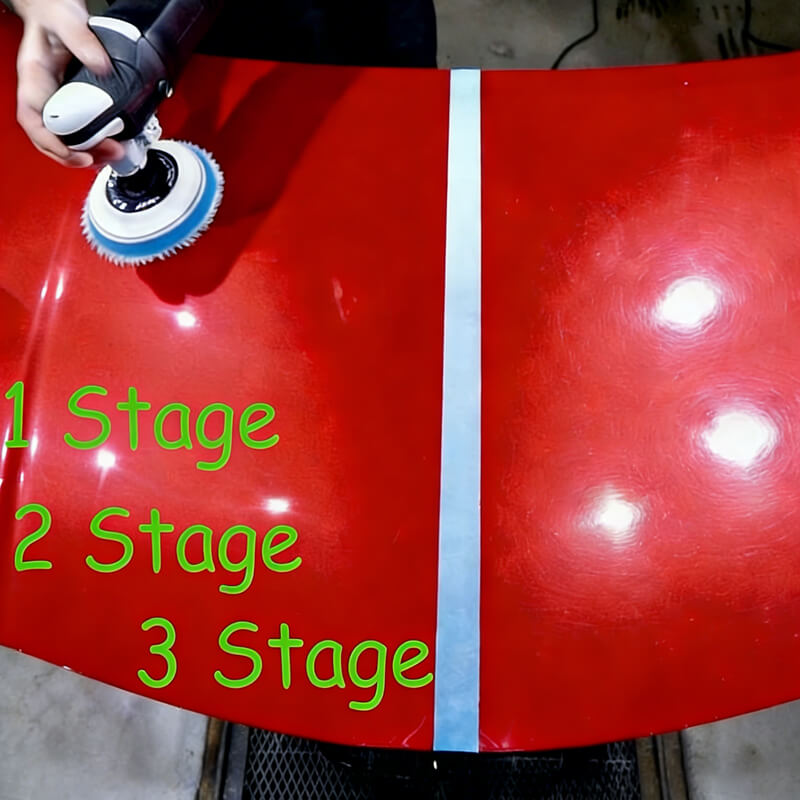

Coarse polishing compounds play a critical role in professional automotive paint restoration and body-shop workflows. Designed for aggressive cutting and rapid removal of deep scratches, oxidation, heavy swirl marks, and overspray, coarse polishing compounds are the first step in a staged paint-correction process. Understanding their composition, appropriate use, and how to integrate them into a multi-step polishing system is essential for achieving consistent, high-quality results while protecting the vehicle’s clear coat.

What are coarse polishing compounds?

Coarse polishing compounds are abrasive pastes formulated with relatively large abrasive particles and binders that enable controlled material removal. Common abrasive media include aluminum oxide and silicon carbide; manufacturers and chemists adjust particle size distribution, binder chemistry, and lubricant content to balance cutting power, smear behavior, and ease of wipe-off. The result is a product engineered to remove surface defects efficiently while leaving a finish that can be refined by subsequent medium and fine polishes.

Primary applications

The typical use cases for coarse polishing compounds include:

• Heavy defect removal — Eliminating deep scratches, sanding marks from P800–P1200 grit or coarser, heavy oxidation, and pronounced water-spot etching.

• Paint leveling — Correcting localized high spots or uneven paint deposition after bodywork.

• Preparation after wet sanding — When wet-sanding with coarse abrasives is necessary, coarse compounds remove the remaining sanding haze.

• Rapid cutting in fleet or collision-repair settings — Where throughput is important and a significant amount of paint correction is required.

Selecting the right tools and consumables

Coarse compounds are most effective when paired with the appropriate pad and machine. Typical recommendations:

• Pads: Wool or heavy-cut foam pads provide aggressive cutting action. For rotary machines, consider wool or dense foam that tolerates higher heat. For DA (dual-action) polishers, select a firm-cut foam pad formulated for cutting.

• Machines: Rotaries deliver the fastest cutting but require experienced operators to avoid clear-coat burn-through. High-quality DA polishers are safer for less experienced operators and still effective with the right compound and pad.

• Speeds & pressure: Use moderate to high speed settings only where safe (rotary: operator-experienced; DA: recommended mid-range RPM). Apply consistent, moderate pressure — excessive pressure increases heat and risk of clear coat damage. Always perform a test spot.

Procedure and best practices

1. Inspect & prepare: Clean and decontaminate the surface. Clay-bar or decontamination steps remove embedded contaminants that can accelerate abrasive wear or create additional scratches.

2. Test spot: Always perform a small test to confirm the compound/pad/machine combination produces the desired cut without excessive haze or heat.

3. Work systematically: Divide panels into manageable sections, maintain pad flatness, and overlap passes. Wipe the residue periodically to evaluate progress.

4. Follow the staged approach: After coarse cutting, progress to medium and fine polishes to remove micro-marring and restore gloss. Finish with a high-gloss polish and protective sealant or wax to lock in results.

5. Safety & material preservation: Avoid overworking an area, monitor surface temperature, and do not attempt aggressive cutting on factory-thin or severely worn paint.

Performance metrics and product selection

When selecting a coarse polishing compound, consider:

• Abrasive type and particle-size distribution — dictates cutting aggressiveness and finishing demands.

• Binder and carrier formulation — affects ease of application, smear, and residue removal.

• Compatibility with subsequent polishes — a compound that leaves a manageable finish reduces time spent polishing with finer abrasives.

• Packaging & shelf life — look for consistent batch control and clear storage guidance.

SYBON — Professional-grade manufacturing with competitive pricing

SYBON is a professional manufacturer and supplier of automotive polishing compounds based in China. We provide a comprehensive range of coarse polishing compounds engineered for body shops, detailers, fleet operators, and auto-repair centers. SYBON’s production capabilities include modern manufacturing lines and quality-control equipment that enable consistent formulation, tight batch tolerances, and reliable performance. Although SYBON may not have the name recognition of certain global brands, our products are formulated and tested to deliver comparable cutting power and finishing behavior — at a significantly more attractive price point.

Why choose SYBON coarse polishing compounds?

• High performance: Formulations optimized for aggressive defect removal while maintaining wipe-off and finishability.

• Cost-effectiveness: Competitive wholesale pricing with consistency that helps dealers and distributors protect margins.

• Product range: Complete system solutions — from coarse cutting compounds through to fine polishes and finishing glazes — allowing end users to standardize on SYBON for a multi-step workflow.

• Quality assurance: Production and inspection processes designed to ensure product uniformity between batches.

• Support for distributors and dealers: SYBON actively works with agents, paint-shop owners, and repair centers, offering sample testing and technical advice to help integrate our compounds into local service offerings.

Partnering for market success

SYBON seeks global agency and distribution partnerships. We welcome distributors, polishing product dealers, body-shop owners, and fleet maintenance managers to request samples for evaluation. For businesses aiming to improve repair quality while optimizing cost, SYBON’s coarse polishing compounds provide a practical, high-value solution that helps you compete effectively in local markets and improve service profitability.

Contact & next steps

If you are an agent, paint-shop owner, or business interested in becoming a distributor, please contact SYBON through our website contact form or send an email via the website. We welcome sample requests and will respond within 24 hours to discuss pricing, packaging options, minimum order quantities, and technical support. Partner with SYBON to offer high-performance coarse polishing compounds that help your customers restore paint surfaces quickly and reliably — without paying a premium for brand-name markup.

Conclusion

Coarse polishing compounds are indispensable tools for professional paint correction. When selected and used correctly, they accelerate defect removal and form the foundation of a controlled, multi-step restoration process. SYBON combines robust manufacturing, quality assurance, and competitive wholesale pricing to deliver coarse polishing compounds that meet the needs of professional detailers and repair shops. If you want quality comparable to major brands but with better cost efficiency and responsive support, SYBON is a partner worth evaluating.

Source of this article:https://www.sybonbest.com

Get to know us through more channels: