Maximize Shine with a Cheap Polishing Compound: SYBON’s Superior Quality at a Smart Price

In the world of automotive care, few products are as essential—and as misunderstood—as the polishing compound. Whether you’re a professional detailer, an amateur enthusiast, or a distributor looking to expand your product line, understanding the ins and outs of polishing compounds is the first step toward achieving showroom‑quality finishes and building a thriving business. In this article, we’ll begin with an overview of polishing compound technology, then explore why “cheap polishing compound” can be both an opportunity and a pitfall, and finally introduce SYBON’s high‑performance, cost‑effective solutions and outstanding after‑sales service.

1. Polishing Compound: Industry Knowledge and Best Practices

Polishing compounds are specialized abrasives suspended in a lubricant or carrier, designed to remove fine scratches, swirl marks, oxidation, and other surface defects from automotive paint, gelcoat, clear coats, and even metal and plastic trim. They typically fall into three broad categories:

1. Heavy-Cut Compounds – Formulated with coarser abrasives, these are perfect for correcting deep scratches, heavy oxidation, and acid rain etching. They restore uniformity to weathered surfaces but leave micro‑marring that requires subsequent refinement.

2. Medium-Cut Compounds – With a balance of aggressiveness and finesse, these compounds tackle moderate defects while producing a smoother finish. They’re the workhorses of many detail shops.

3. Finishing Polishes – Using ultra‑fine abrasives, these polishes refine the surface to a high gloss, removing any micro‑marring left by heavier compounds and preparing the paint for waxes, sealants, or ceramic coatings.

Key factors that distinguish one polishing compound from another include abrasive type (aluminum oxide, silicon carbide, or proprietary blends), abrasive particle size distribution, carrier viscosity, and the inclusion of lubricants or protective additives. Matching the right compound to the paint system, substrate, and defect severity is critical for both efficiency and end‑result quality.

Beyond formulation, effective polishing also depends on:

1. Pad Selection: Foam, wool, or microfiber pads with varying densities and cell structures.

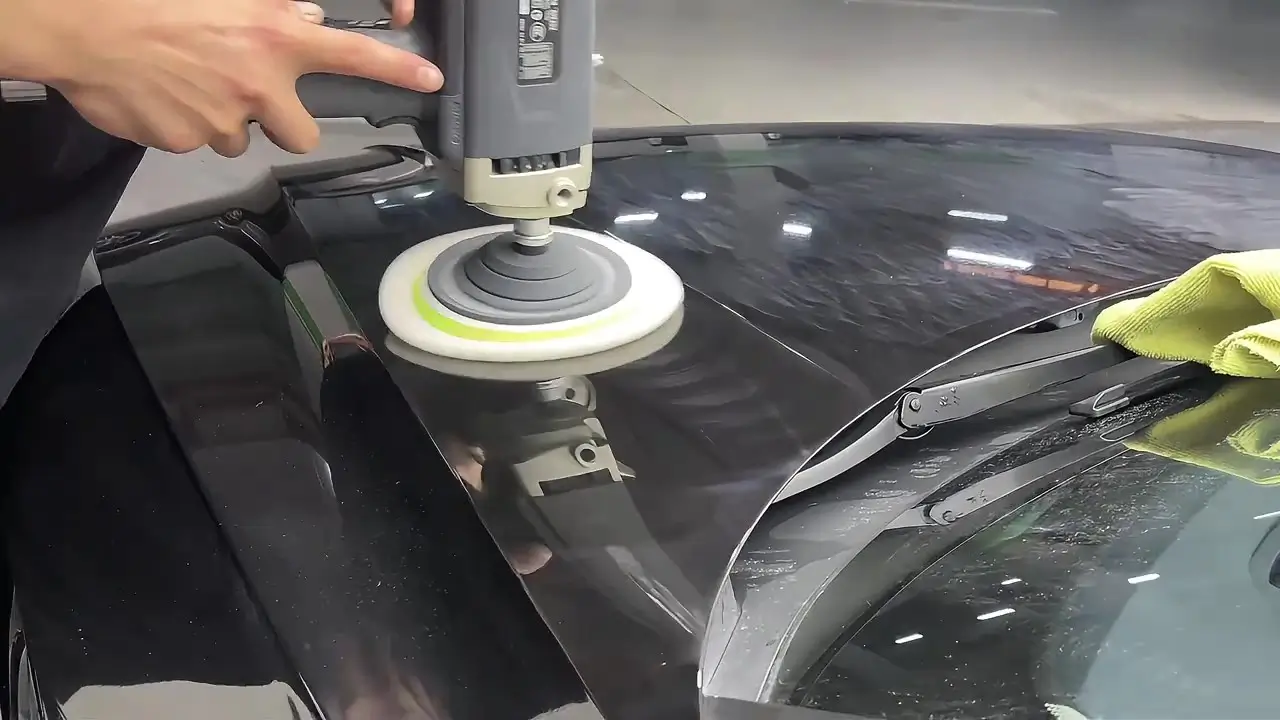

2. Polisher Type: Rotary versus dual‑action machines, each with unique heat generation and cut characteristics.

3. Technique: Speed, pressure, and working time under the pad all influence compound performance and final gloss.

Understanding these nuances empowers professionals and distributors alike to make informed purchasing decisions—and to convey real value to end customers.

2. The Appeal and Risks of “Cheap Polishing Compound”

The phrase cheap polishing compound immediately catches the eye of cost‑conscious buyers. On the surface, acquiring abrasive compounds at rock‑bottom prices seems like a straightforward way to cut overhead—especially for small shops, mobile detailers, and new distributors eager to keep inventory costs low. However, there are several hidden considerations that accompany low price tags:

1. Abrasive Consistency: Cutting corners on raw materials often leads to uneven particle sizes, which can leave inconsistent surface finishes or even embed larger grit particles that scratch the paint.

2. Lubricant Quality: Inadequate carriers can burn or clog pads, increase frictional heat, and reduce working time—undermining both safety and efficiency.

3. Chemical Stability: Inferior compounds may separate over time, require constant agitation, or suffer from premature hardening or microbial growth in water‑based formulations.

4. After‑Sales Support: When performance issues arise, many ultra‑low‑price suppliers have minimal service infrastructure, limited technical training, and slow response times—or none at all.

In other words, while cheap polishing compound options can deliver short‑term savings, they risk long‑term frustration, wasted labor hours, potential damage to vehicles, and negative customer feedback. For distributors and detailers seeking sustainable growth, product performance and reliable service are non‑negotiable.

3. SYBON: Premium Quality Meets Affordable Pricing

SYBON’s philosophy challenges the assumption that high quality and robust after‑sales support must come at a premium. As a professional manufacturer of automotive polishing compounds with decades of experience, SYBON invests heavily in:

1. Rigorous Quality Control: Multi‑step inspection processes ensure every batch meets tight abrasive size distributions and stability metrics.

2. Advanced Formulations: Proprietary blends that balance cut, finish, and lubricant—yielding fast defect removal without glaze or hazing.

3. Comprehensive Technical Support: Training videos, in‑person workshops, troubleshooting guides, and 24‑hour response times to empower distributors and end‑users.

While SYBON’s polishing compounds are not the cheapest on the market, they offer exceptional value when compared with large global brands. In fact:

1. Price Point: SYBON compounds are typically 20–30% less expensive than tier‑one international brands, making them highly competitive for distributors seeking margin‑friendly products.

2. Performance Parity: Independent tests confirm that SYBON’s heavy‑cut, medium‑cut, and finishing polishes deliver scratch‑removal efficiency and gloss levels on par with, or even surpassing, many established leaders.

3. Service Excellence: SYBON’s dedicated after‑sales team guarantees technical support, rapid replacement for any manufacturing defects, and customized advice for new applications.

In short, SYBON combines the prestige and reliability of big‑name products with the affordability and agility of a specialized manufacturer—delivering a truly cheap polishing compound alternative that doesn’t compromise on quality or support.

4. Why Choose SYBON for Your Automotive Care Line?

If you’re a distributor, detail shop owner, fleet manager, or body‑shop operator, here’s why SYBON should be your go‑to supplier:

1. High‑Performance Products

– Heavy‑cut compounds that tackle the toughest defects

– Medium‑cut options that handle everyday swirl removal

– Finishing polishes that deliver a flawless showroom shine

2. Competitive Pricing

– Substantially lower cost than multinational brands

– Bulk packaging and tiered pricing for volume orders

– No hidden fees—transparent shipping and handling

3. Outstanding After‑Sales Service

– 24‑hour technical response guarantee

– Comprehensive documentation and training resources

– Rapid replacement policy for any manufacturing issues

4. Global Distribution Opportunities

– SYBON is actively seeking agents and distributors worldwide

– Flexible partnership models—exclusive territories or open distribution

– Marketing support, co‑branded materials, and sales incentives

5. Partner with SYBON for Mutual Success

SYBON may not yet have the same global household name as some legacy brands, but our uncompromising approach to product quality, combined with cost‑effective pricing and unparalleled after‑sales support, makes us the ideal partner for growing your automotive care business. If you’re frustrated by the high price points of other brands or disappointed by the inconsistent performance of “cheap polishing compound” knock‑offs, it’s time to experience the SYBON difference.

1. Sample Testing: Request samples for in‑shop evaluation.

2. Technical Consultation: Our experts will help you choose the right formulations for your market’s needs.

3. Marketing Assistance: Co‑op advertising funds, POS materials, and social‑media content to drive sales.

If you are an automotive distributor, body‑shop owner, paint shop manager, or any business involved in vehicle maintenance and detailing, SYBON invites you to explore our full range of polishing compounds and related care products. Contact us today via the inquiry form on our website or send an email to us. A SYBON representative will reach out within 24 hours to discuss how we can help you elevate your offerings, boost customer satisfaction, and maximize your profits.

Source of this article:https://www.sybonbest.com

Get to know us through more channels: